World-class milling environment

Safe and hygienic production environment

- Taiwan's 1st all positive pressure ventilation mill to meet pharmaceutical plant: Fully isolating the mill from all external contamination.

- Integrated dust collection equipment: Effectively eliminating dust contamination.

- Central integrated vacuum system: Effectively maintains a clean mill space.

- Variable-frequency rodent and insect repelling equipment: Uses multiplex modulated sweeping ultrasonic sounds to ensure a safety and hygienic environment free of rodents and insects.

- Double automated warehouse doors: Prevents foreign objects from entering the warehouse and coming into contact with items stored in the warehouse, thereby ensuring the quality and hygiene of the storage items.

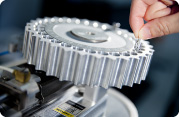

Taiwan’s most advanced milling equipment

- Fully-automated, central-computer-controlled milling system: Italian OCRIM milling equipment and a fully-automated control system are adopted to enhance efficiency, quality, and stability; the system can process 760 ton of wheat per day.

- First mill to use automated sorters: A color sorter is adopted to achieve accurate wheat sorting through the optical detection of debris and inferior grains.

- Advanced and environmentally friendly milling equipment: Imported Italian whole mill equipment that complies with UNI EN 1672-2 standards is used; it affords high accuracy and different hardness designs to enhance productivity and yield; the special belt design effectively minimizes noise pollution.

- Screening equipment: A special intermediary screening design is adopted to enhance flour quality.

- Modernized warehousing: Color-coded to indicate different product storage locations, work zones, and walkways, thereby achieving fast and accurate operations while ensuring environmental safety and efficiency.

- Maintains highest food safety standards: To ensure hygiene and safety, equipment that contacts with flour is built with food grade material.

Leading quality assurance instruments and personnel

Stringent quality management system

- World-class inspection equipment: Operates Taiwan’s most advanced and complete inspection equipment.

- Professional quality management team: All QC personnel specialize in food science; over 60% hold a master’s degree in a food-related specialization; all personnel are currently involved in continued education.

- Professional secondary processing laboratory: Processing tests are conducted using professional Kitchen Laboratory by professional bakers to ensure product quality.

- Food safety accreditation: Passed SQF (Safe Quality Food)-the highest level certification, ISO 22000 Food Safety Management Systems, Hazard Analysis and Critical Control Points (HACCP), HALAL certification, Clean Label, Good Hygienic Practices (GHP), Taiwan Quality Food (TQF).

Quality Control Instruments

|

1.Viscograph-E: |

|

2.Near Infrared (NIR) Spectroscopy: |

|

3. Extensograph-E: |

|

4.Mixolab: |

|

5.Farinograph-E: |

|

6.Mobile sample storage unit: |

|

7.Gluten washing machine: |

|

8.Dumas protein analyzer: |